Announcement

Collapse

No announcement yet.

Conversion of flux core wire feed welder to MIG

Collapse

X

-

Ordered the regulator, solid core wire, solenoid and nozzle/tips suggested in video. Will pick up the misc. parts (hose, fittings, etc.) from the local hardware store. Still need to get a tank for shielding gas. Local Tractor Supply Store sells 20# Argon/CO2 mix for about $30 bucks but they want $140 for the tank. Going to see if I can find a used one as they just get exchanged upon refill anyway...

-

So went on craigs list and only found a couple of tanks but they were really old and fairly expensive. So Tractor Supply wanted $239 for an EMPTY 40# (decided to go one bigger than the small one) Thoroughbred industrial (i.e., DOT rated) tank. I searched for a couple hours last night and they were all about the same price (shocked really). Ended up finding the same one as TSS (important so I can exchange it for a full tank) on Northern Tool for $220. Searched for a discount code and found one for $25 off $100 or more, so $195. $214 after shipping. So saved a little more than 20% after some searching, I'll take it. Still need to exchange it and $40 for a full 75% AR/ 25% CO2 tank.

So, who's got some welding projects? LOL...

- 2 likes

Comment

-

OK so got the parts and worked on it this morning.

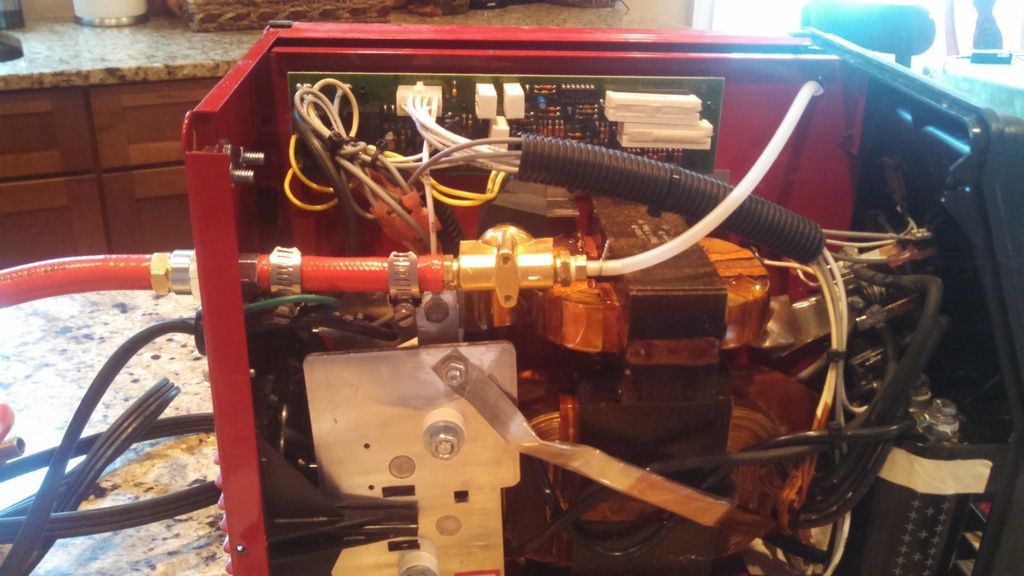

Mounted and connected gas solenoid inside welding case:

Top view with homemade bracket out of a piece of aluminum flat stock that I had in the garage. Yellow wires are coming off the new solenoid. Connected the input side with a piece of 3/8" air hose and output side with 1/8" polyethylene. Used a piece of stainless bail wire to clamp the small hose.

New tank and regulator. Actually need to get a 3/8" hose bib for the tank as it came with 1/4".

Connection of 1/8" tube to gun. Hose bib was already on the machine. Polarity needed to be reversed on the gun connections for welding with shielding gas.

Also needed to buy a gas nozzle and .030 tip for new solid core wire.

- 2 likes

Comment

-

It's basically a hobby welder only 20% duty cycle at 88 amps but I'm not planning to use it for continuous welding. Main job that I need to do is my truck's rear arch panel, which is going to be a long series of stacked tack welds at relatively low current. Pretty sure it will handle that without a problem.

Comment

-

Picked up a welding cart from Harbor Freight. Say what you will but tell you what, can't beat HF for crap like this. Picked it up on sale for $45 and 20% off code so approx. $35 before shipping. It shipped quick and is pretty sturdy. Didn't like the cheap Chinese hardware that was supplied with it so used some 1/4" bolts I had in the garage and threw a tie down strap around the tank for good measure.

Also couldn't find a 3/8" hose bibb with the right threads so went with a stainless braid dishwasher hose.

Can't wait for the wheel arch panel to get here, LOL!!!

- 1 like

Comment

Comment